Food Industry

Reduce Water Heating Costs

The food industry is heavily dependent on fossil fuels and significantly contributes to Green House Gas emissions.

The EscoPod can reduce CO2 emissions by 60% and save up to 80% on water heating costs!!

The EscoPod is a prefabricated thermal energy centre, incorporating turbine driven heat pump technology, that is delivered to your site and takes over from your boiler plant to deliver hot water at a fraction of the cost and with massive energy and CO2 savings.

Between processing, refrigeration, hot water and steam, the meat industry has a constant requirement for hot water. This high, regular demand for both heating and power make the meat industry an ideal candidate for the EscoPod.

ABP Food Group processes more than one million cattle annually at 20 sites throughout Ireland, the UK and Poland, and are one of Europe’s leading supplier of premium grass-fed beef. Like all meat processing facilities, they use large quantities of hot water to ensure plant and equipment is cleaned daily after each shift and for sterilisation and handwashing. This incurs the financial and environmental cost of heating this water!

As an innovative and forward-thinking company, who have a huge focus on sustainability, ABP knew their systems needed total reform and chose the EscoPod as the solution to their problems!

“We needed an innovative solution that would totally reform our heat generation and distribution network. And we found it. In the EscoPod”

Installed in late 2015 in Nenagh, the EscoPod has resulted in a 20% reduction in CO2. It now provides 95% of the site’s heating requirements, replacing those heavy fuel boilers. It also generates electricity for the plant and helps recover heat from the refrigeration process to reuse elsewhere.

In effect, ABP Nenagh has eliminated its need for fossil fuels to generate hot water. It has also dramatically exceeded almost all its the sustainability targets within a single year.

The EscoPod

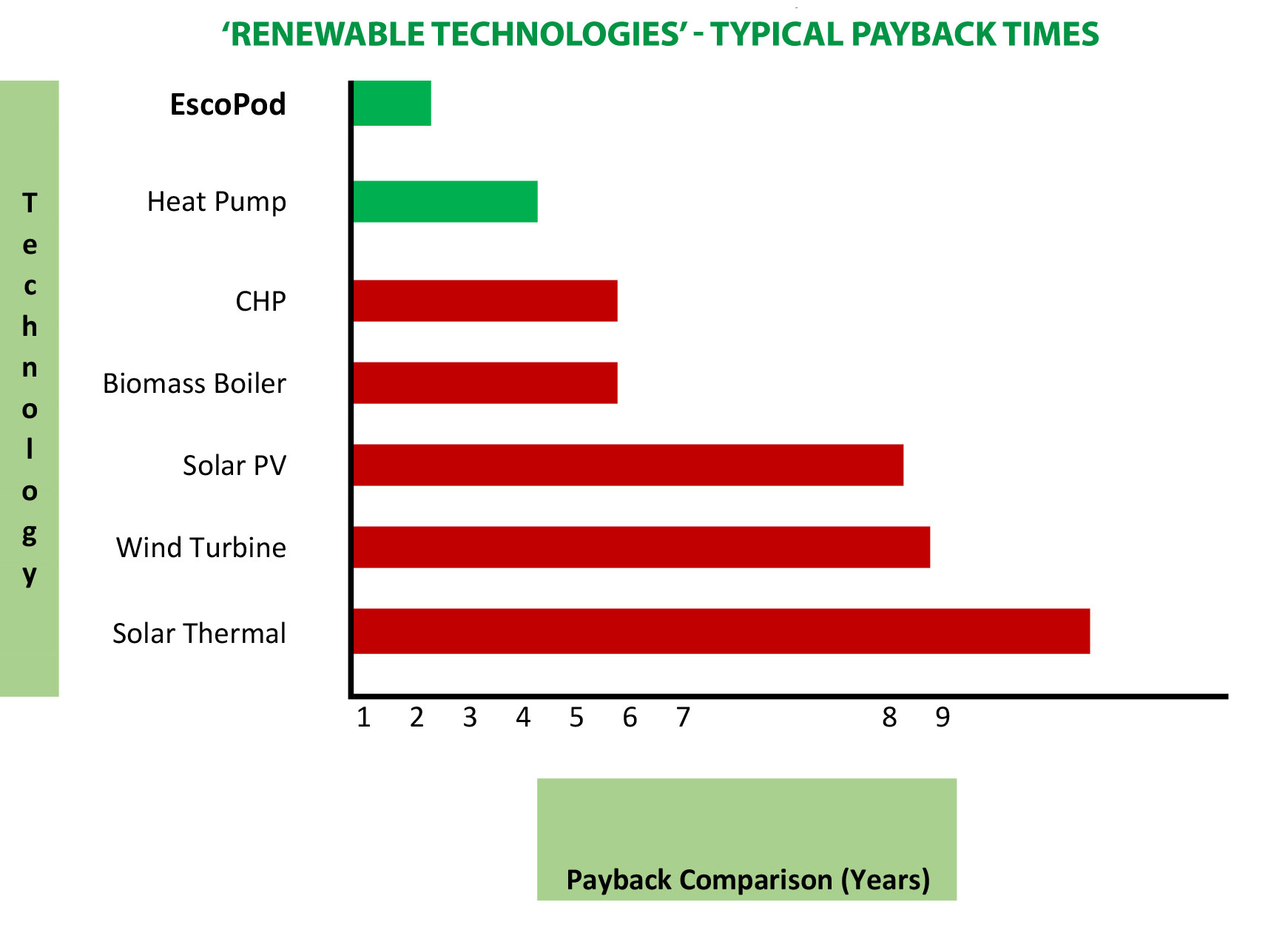

“The EscoPod outperforms all other thermal heating systems, making sustainability profitable.”

The EscoPod is a prefabricated thermal energy centre, incorporating turbine driven heat pump technology, that is delivered to your site and takes over from your boiler plant to deliver hot water at a fraction of the cost and with massive energy and CO2 savings.

Heat Pumps are tested when asked to deliver high temperature water, consume power that may not be available, and their economic feasibility is vulnerable to rising electricity prices.

The EscoPod delivers 90°C water; generates its own power; and is resistant to rising electricity prices.

Testimonials

Here’s what our clients had to say about our services:

“We needed an innovative solution that would totally reform our heat generation and distribution network. And we found it. In the EscoPod”.

Installed in late 2015 in Nenagh, the EscoPod has resulted in a 20% reduction in CO2. It now provides 95% of the site’s heating requirements, replacing those heavy fuel boilers. It also generates electricity for the plant and helps recover heat from the refrigeration process to reuse elsewhere.

In effect, ABP Nenagh has eliminated its need for fossil fuels to generate hot water. It has also dramatically exceeded almost all its the sustainability targets within a single year.

(Source: Irish Food Magazine, 2017)